In the rapidly evolving field of robotics, the performance and precision of robotic arms depend heavily on the quality of their bearings. Bearings are the backbone of smooth and efficient motion, ensuring that robotic joints move accurately and reliably. At Yuwei-bearing, we specialize in designing and manufacturing the best bearings for robotics, combining advanced engineering, superior materials, and strict quality control to deliver exceptional performance for industrial and collaborative robotics.

Best Bearings for Robotics and User Guide

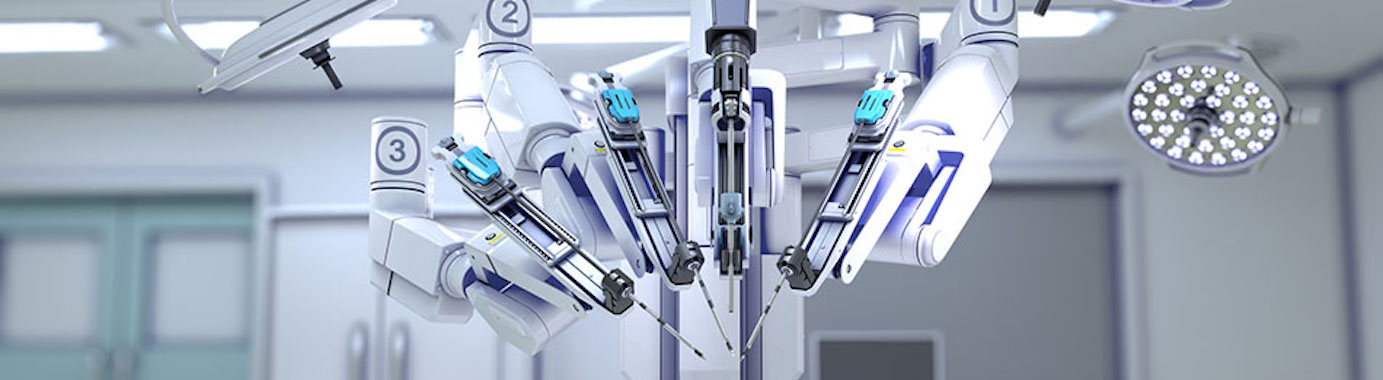

Robot arm bearings are essential components that support key joints such as shoulders, elbows, wrists, and end-effectors. They enable controlled rotation and linear motion while minimizing friction and wear. This ensures that robots can perform precise, repeatable tasks efficiently, which is critical for industrial automation, high-precision applications, and collaborative robots working safely alongside humans.

With decades of engineering expertise and cutting-edge manufacturing processes, Yuwei-bearing produces bearings that maximize efficiency, reduce maintenance, and provide long-lasting reliability.

1. Types of Bearings Used in Robotics

Bearings vary depending on the application requirements, motion type, and load:

-

Deep Groove Ball Bearings: Handle both radial and axial loads; ideal for medium-load robotic arms.

-

滚子轴承: Provide high rigidity and can support heavy loads.

-

Spherical Bearings: Self-aligning to compensate for angular misalignment, ideal for multi-directional loads.

Yuwei-bearing ensures that each bearing is manufactured with precise tolerances, premium materials, and advanced engineering for optimal performance, durability, and smooth motion in any robotic application.

2. Precision Bearings for Robotic Joints and Movement

Precision is critical in robotic arms performing delicate or repetitive tasks. Precision bearings for robotic arms minimize backlash, vibration, and inaccuracy, ensuring smooth, repeatable movement.

-

Angular Contact Bearings: Handle combined radial and axial loads for high-speed, high-precision applications.

-

Miniature Ball Bearings: Perfect for compact robots where space and weight are limited.

By using the best bearings for robotics, Yuwei-bearing ensures that your robotic arms maintain exact positioning, improve motion efficiency, and achieve long-term reliability.

3. Cross Roller and Thin Section Bearings

Cross roller bearings provide high rigidity and support multi-directional loads, making them perfect for industrial robotic arms. Thin section bearings offer lightweight, compact solutions without sacrificing stiffness or accuracy—ideal for collaborative robots.

在 Yuwei-bearing, these bearings are manufactured with superior materials and precision engineering, delivering exceptional stiffness, smooth rotation, and long-lasting performance under all operational conditions.

4. Miniature and Instrument Bearings for Compact Robots

Miniature bearings are essential for lightweight robotic arms, cobots, and educational robots. They reduce friction, maintain smooth rotation, and ensure accurate movement in tight spaces.

Our miniature bearings are crafted for durability, high-speed performance, and low maintenance. With Yuwei-bearing, even the smallest robotic systems achieve maximum motion control, efficiency, and reliability.

5. High-Load Bearings and Ball Screw Support Bearings

Heavy-duty robotic arms require bearings capable of withstanding substantial axial and radial loads while maintaining precision.

-

High-Load Bearings: Engineered to maintain stability and smooth motion under heavy-duty conditions.

-

Ball Screw Support Bearings: Reduce axial play and improve linear motion accuracy.

-

Spherical Bearings: Self-aligning to handle angular misalignment while supporting heavy loads.

Choosing the Right Bearing for Your Robotic Application

Selecting the right bearing requires analyzing load capacity, precision needs, operating conditions, and robot type. Industrial robots need high-load, high-precision bearings, while collaborative robots benefit from lightweight, low-friction options.

Yuwei-bearing offers custom solutions for both precision bearings for robotic arms and high-load bearings for robotic arms, ensuring that each robotic system receives the best bearings for robotics to achieve optimal efficiency, durability, and reliability.

1. Materials Used in Robot Arm Bearings

The choice of material affects bearing performance and longevity:

-

Steel Bearings: Durable, strong, and corrosion-resistant.

-

Ceramic Bearings: Lightweight, thermally stable, and ideal for high-speed applications.

-

Surface Treatments & Coatings: Reduce friction, wear, and environmental exposure.

Us carefully select materials and coatings to deliver bearings that outperform standard solutions in strength, load capacity, and operational life.

2. Maintenance and Lubrication of Robot Arm Bearings

Proper lubrication reduces friction, prevents overheating, and extends bearing life. Depending on the application, grease, oil, or specialty lubricants may be used. Routine maintenance, including cleaning and timely replacement, ensures consistent performance.

Pur Services are best to maximise efficiency and longevity, ensuring your robotic arms continue operating smoothly and reliably.

3. Quality Standards and Certifications

All Yuwei-bearing products meet or exceed ISO and industry standards. Each bearing undergoes rigorous testing for load capacity, precision, and durability.

This commitment to quality guarantees that our customers receive the best bearings for robotics, ensuring safety, reliability, and exceptional performance in all applications.

4. Future Trends in Robotics Bearings

Robotics bearings are evolving with lightweight materials, smart sensors for condition monitoring, and AI-assisted predictive maintenance. These advancements enhance efficiency, precision, and reliability in robotic systems. Yuwei-bearing is at the forefront of innovation, producing next-generation bearings that meet the demands of tomorrow’s robotics industry.

Q1. What makes Yuwei-bearing the best choice for robot arm bearings?

Yuwei-bearing offers high-quality precision and high-load bearings designed for smooth motion, durability, and long-term reliability, ensuring your robotic arms perform efficiently under all conditions.

Q2. What types of bearings are used in robotic arms?

Robotic arms use precision bearings, miniature bearings, cross roller bearings, thin section bearings, ball screw support bearings, and spherical bearings, each designed to handle specific loads and motion requirements.

Q3. How do high-load bearings benefit industrial robotic arms?

High-load bearings support heavy axial and radial loads while maintaining stability and smooth motion, which is essential for industrial robots performing lifting, assembly, or repetitive tasks.

Q4. Can Yuwei-bearing provide bearings for compact or collaborative robots?

Yes. Our miniature and precision bearings are designed for compact robots and collaborative systems, ensuring smooth, accurate motion in limited spaces without compromising performance.

Q5. How should robot arm bearings be maintained for optimal performance?

Regular lubrication, inspection, and timely replacement are crucial. Yuwei-bearing provides guidance on maintenance schedules to maximize the lifespan and efficiency of your robotic bearings.

Selecting the right bearings is crucial for the performance, precision, and longevity of any robotic arm. With Yuwei-bearing, you get the best bearings for robotics, designed to deliver unmatched durability, high-load capacity, and precise motion. Our range of precision bearings for robotic arms and high-load bearings for robotic arms ensures that every joint and actuator operates smoothly, efficiently, and reliably.

By choosing Yuwei-bearing, you invest in products engineered with advanced materials, rigorous quality control, and expert design—giving your robotics systems superior performance, reduced maintenance, and longer operational life.

For any robotic application, from compact cobots to heavy-duty industrial arms, Yuwei-bearing provides the ultimate solution for precision, reliability, and efficiency.