An articulated robot joint is the mechanical core of modern industrial robots, enabling controlled rotary motion, load transfer, and positional accuracy. Its design directly influences robot stiffness, repeatability, payload capacity, and long-term operational reliability.

From automotive welding lines to precision electronics assembly, articulated joints allow robots to mimic human arm motion with multiple degrees of freedom. Each joint integrates bearings, gears, motors, and housings into a compact, load-bearing system.

Understanding articulated robot joints requires more than basic mechanics. It demands insight into real load behavior, bearing stiffness, drive integration, lubrication strategy, and failure modes that only emerge under continuous industrial operation.

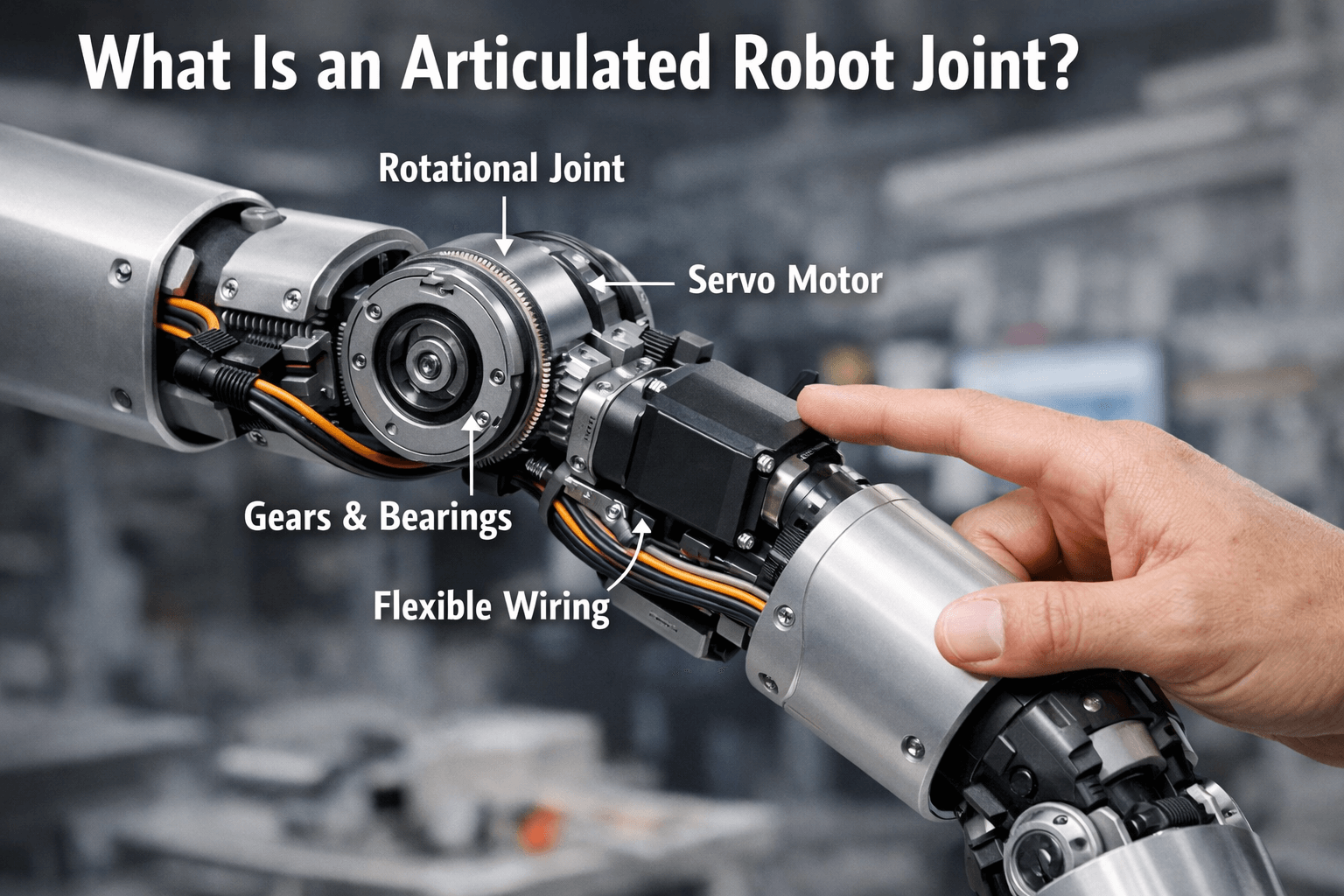

What Is an Articulated Robot Joint?

An articulated robot joint is a rotational axis that connects two robot links and allows controlled angular motion. Unlike linear or fixed joints, articulated joints provide flexibility, reach, and orientation control, making them essential for six-axis industrial robots.

Each joint typically includes:

-

A bearing system

-

A gear reducer (harmonic or cycloidal)

-

A servo motor

-

A rigid housing structure

Together, these components form a structural and motion-control unit, not just a rotating element.

Types of Joints in an Articulated Robot Arm

Articulated robots usually consist of six rotary joints, each with a different mechanical role.

Base Joint (Axis 1)

Supports the entire robot mass and manages high moment loads during rotation.

Shoulder Joint (Axis 2)

Handles the highest torque, lifting the arm and payload against gravity.

Elbow Joint (Axis 3)

Controls reach and arm extension, directly affecting positioning accuracy.

Wrist Joints (Axis 4, 5, 6)

Provide tool orientation, fine motion control, and high repeatability.

Load Characteristics in Articulated Robot Joints

In real applications, robot joints experience dynamic and combined loads, not static conditions.

Key load types include:

-

Radial loads from arm weight and gears

-

Axial loads from vertical motion and tooling forces

-

Moment loads caused by extended reach

-

Shock loads during acceleration, deceleration, and emergency stops

Engineers typically design joints with 2–3× safety factors to ensure durability under unpredictable operating conditions.

Role of Bearings in Articulated Robot Joints

Bearings are the structural backbone of articulated joints. Their stiffness and accuracy directly determine robot performance.

Common bearing functions include:

-

Supporting combined radial, axial, and moment loads

-

Maintaining joint rigidity under torque

-

Minimizing friction and backlash

-

Preserving positional accuracy over time

In high-performance robots, bearing selection is as critical as motor or controller selection.

Bearing Types Used in Articulated Robot Joints

Cross Roller Bearings

Widely used due to their ability to handle all load directions with high rigidity in a compact design.

Common applications: Base, shoulder, elbow, wrist joints

Angular Contact Ball Bearings

Used in matched pairs to manage combined loads where higher speed is required.

Common applications: Shoulder and wrist joints

Thin-Section Bearings

Preferred in compact wrist designs and collaborative robots due to low weight and space efficiency.

Tapered Roller and Slewing Bearings

Applied in heavy-payload robots where extreme load and moment capacity are required.

Integration of Bearings with Gear Drives

Modern articulated robot joints rarely treat bearings and gears as separate systems.

Most designs integrate:

-

Bearings directly into harmonic drive housings

-

Preloaded bearing-gear assemblies

-

Compact joint modules with reduced interfaces

This integration improves stiffness, reduces misalignment, and extends service life, especially under cyclic industrial loads.

Precision, Stiffness, and Repeatability

Joint stiffness is a critical but often misunderstood factor.

Higher stiffness results in:

-

Better path accuracy

-

Improved tool center point (TCP) stability

-

Reduced vibration during high-speed motion

Even if a bearing meets load ratings, insufficient stiffness can degrade robot accuracy, especially at the wrist where small deflections are amplified.

Lubrication and Sealing Considerations

Proper lubrication ensures long-term joint reliability.

Common industrial practices include:

-

Sealed-for-life bearings in wrist joints

-

Long-life grease lubrication for base and shoulder joints

-

Controlled re-lubrication intervals

Over-lubrication, incorrect grease selection, and contamination are among the most common causes of premature joint failure.

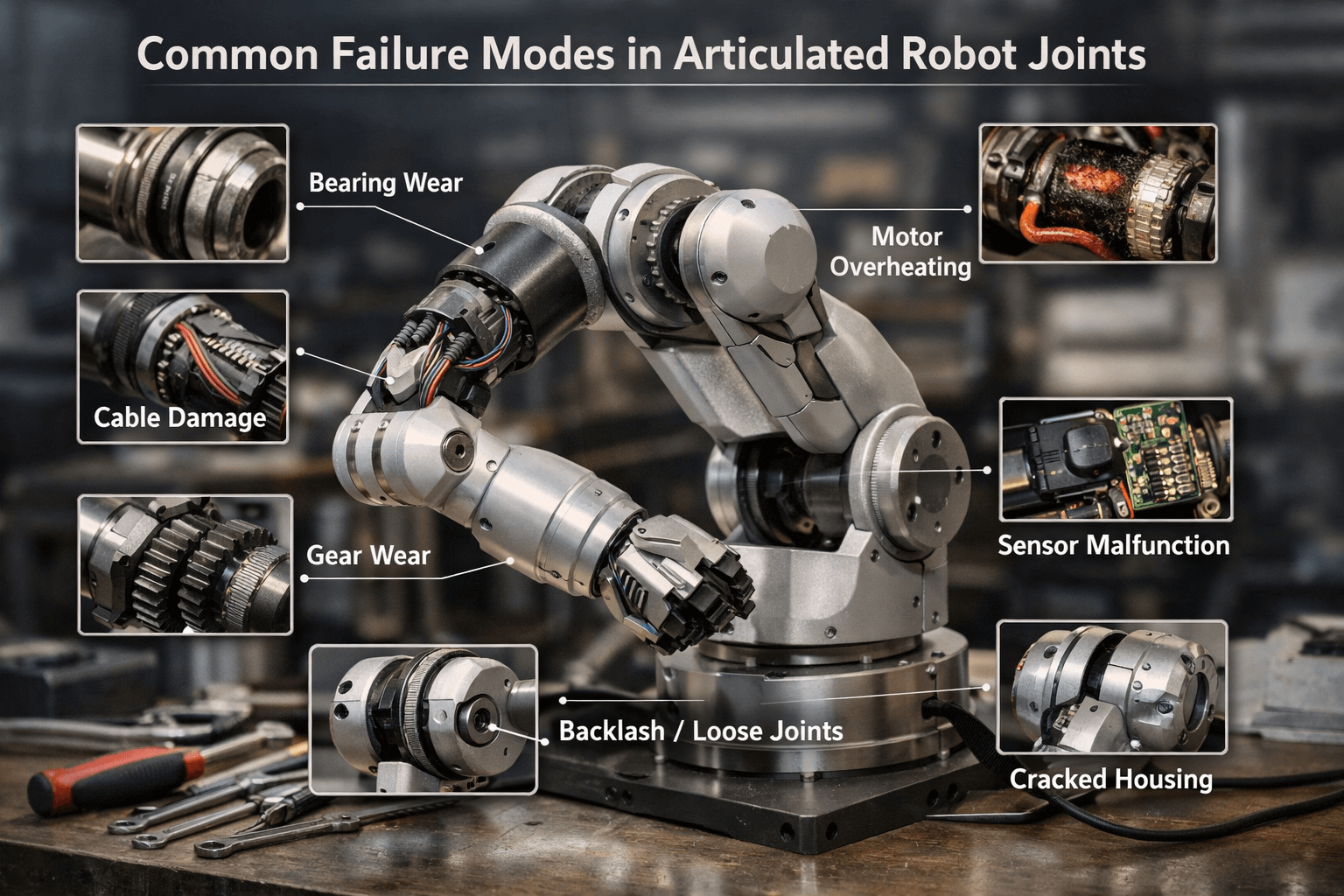

Common Failure Modes in Articulated Robot Joints

Field experience shows most failures are system-level, not component-level.

Typical issues include:

-

Bearing fatigue from underestimated moment loads

-

Lubrication breakdown due to heat or contamination

-

Misalignment caused by poor housing tolerances

-

Excessive preload leading to heat and wear

Preventive design and correct assembly practices eliminate most of these problems.

Advanced Trends in Articulated Robot Joint Design

Modern developments focus on:

-

Integrated joint modules

-

Lightweight materials with higher stiffness

-

Smart bearings with condition monitoring

-

Maintenance-free joint designs

These innovations support higher robot speeds, improved energy efficiency, and predictive maintenance strategies.

结论

Articulated robot joints are far more than rotational connections; they are precision-engineered systems that define the accuracy, reliability, and lifespan of industrial robots. From bearing selection and load analysis to drive integration and lubrication strategy, every design decision influences real-world performance. As robotics applications demand higher speed, precision, and uptime, joint engineering continues to evolve as a critical discipline.

在 Yuwei-Bearing, we apply deep engineering expertise, application knowledge, and real-world industrial experience to deliver reliable robot joint and bearing solutions that meet the demands of modern automation across industries.