Roller bearing are the hidden workhorses of modern machinery. They endure immense loads, reduce friction, and enable smooth movement in engines, motors, conveyors, and industrial equipment. Yet, despite their robust design, these components are vulnerable. When they fail, the consequences ripple through entire systems—producing unexpected noise, heat, vibration, and sometimes catastrophic downtime.

From subtle surface wear to sudden seizure, bearing failures are rarely random; they are signals of underlying issues such as misalignment, contamination, overloading, or improper handling. In fast-paced industrial environments, even a small failure can halt production lines, escalate maintenance costs, and shorten machinery lifespan. Proper understanding of the causes and preventive measures is crucial for operators, engineers, and maintenance teams who rely on these components daily. By addressing the silent threats before they escalate, businesses can save time, reduce expenses, and ensure equipment operates efficiently.

Roller Bearing Common Causes of Failure and Ways to Prevent Them

In this guide, we will explain the common causes of roller bearing failure and the practical steps to prevent them, providing a clear roadmap for reliable operation.

Roller-bearing quietly carry heavy loads, enabling machines to move with precision. Yet, under stress, wear, or neglect, these crucial components can fail, leading to costly downtime, unexpected noise, and dramatic system damage. Understanding the reasons behind failures and the steps to prevent them is essential for engineers, operators, and maintenance personnel. Visit here!

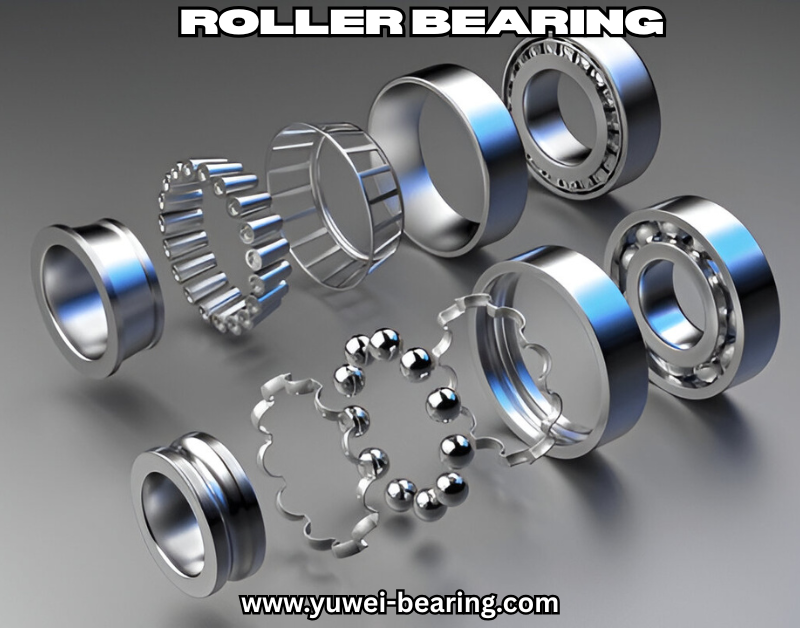

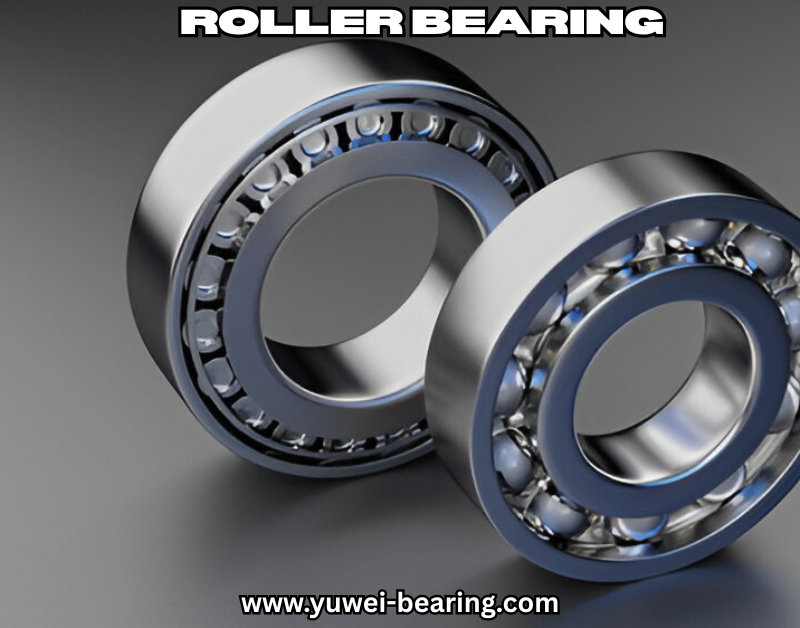

Understanding Roller Bearing

Roller-bearing are mechanical components designed to reduce friction between moving parts while supporting radial and axial loads. They consist of an inner and outer raceway, rollers, and a cage that keeps the rollers evenly spaced. Unlike ball bearings, which use spherical elements, these bearings rely on cylindrical, tapered, or spherical rollers to carry higher loads.

Detailed Guide:

- Types: Cylindrical, tapered, and spherical designs allow specific load management and flexibility.

- Function: Rollers roll instead of slide, reducing friction and distributing load evenly.

- Applications: Common in industrial machinery, automotive transmissions, motors, and high-speed equipment.

Tip: Selecting the right type for your load and speed conditions is crucial for longevity.

Table 1: Roller Bearing Types and Applications

| Type | Load Capacity | Typical Use | Strength | Limitation |

|---|---|---|---|---|

| Cylindrical | High radial | Motors, conveyor shafts | High stiffness | Limited axial support |

| Tapered | Radial + axial | Gearboxes, automotive | Handles combined loads | Sensitive to misalignment |

| Spherical | Radial + axial + misalignment | Heavy machinery | Tolerates shaft deflection | Larger size, heavier |

Common Causes of Roller-Bearing Failure

Failure is rarely accidental. It typically arises from a combination of stress, contamination, poor lubrication, or operational errors. Early recognition of symptoms can prevent catastrophic outcomes.

Key Symptoms to Watch:

- Noise or vibration

- Increased operating temperature

- Surface discoloration or pitting

- Uneven wear

Table 2: Failure Symptoms and Their Indicators

| Symptom | Possible Cause | Immediate Action |

|---|---|---|

| Noise during rotation | Lubrication problem or contamination | Check lubricant and seals |

| Overheating | Overload or friction | Reduce load, inspect bearing |

| Surface damage | Misalignment or fatigue | Realign shaft, replace bearing |

| Vibration | Misalignment or installation error | Inspect mounting and alignment |

Contamination

Foreign particles such as dust, dirt, metal shavings, or water are silent killers for rolling elements. Even microscopic contaminants can scratch raceways, cause flaking, and accelerate wear.

Detailed Guide:

- Causes: Poor sealing, environmental exposure, dirty lubricants, or improper handling.

- Effects: Rough rotation, abnormal noise, heat, premature wear, and potential bearing seizure.

- Prevention:

- Use shields, seals, or labyrinth covers to protect internal surfaces

- Maintain clean installation and operational environments

- Filter or replace lubricants regularly

Tip: Even small contamination can halve the service life of a bearing, making cleanliness a high-priority task.

Overloading

Applying loads beyond the designed capacity stresses the rollers and raceways. Overloading can deform elements, cause micro-cracks, and lead to early failure.

Detailed Guide:

- Causes: Miscalculated load, unexpected operational shocks, uneven load distribution.

- Effects: Surface indentations, flaking, rapid heat buildup, and shortened bearing life.

- Prevention:

- Select bearings rated for actual operating loads

- Avoid sudden impact loads

- Use multiple bearings to share heavy loads if necessary

Table 3: Load Impact on Bearing Life

| Load Level | Life Expectancy | Notes |

|---|---|---|

| Within rating | 100% | Optimal performance |

| 1.5x rating | ~60% | Rapid wear, higher maintenance |

| 2x rating | <20% | Immediate risk of failure |

Misalignment

Even small misalignments between the shaft and housing cause uneven stress distribution. Misalignment can result from poor installation, shaft deflection, or wear in surrounding components.

Detailed Guide:

- Causes: Shaft bending, improper mounting, component deformation over time.

- Effects: Localized wear on rollers and raceways, vibration, early fatigue.

- Prevention:

- Use precision mounting tools and techniques

- Employ self-aligning bearings where unavoidable

- Check alignment during regular inspections

Tip: Misalignment not only shortens life but can also damage associated machinery, multiplying repair costs.

Improper Handling and Installation

Handling errors are surprisingly common. Bearings are precision-machined; small scratches or nicks during handling can compromise surface integrity.

Detailed Guide:

- Causes: Dropping, hitting, using wrong tools, contamination during installation.

- Effects: Premature vibration, surface damage, early fatigue.

- Prevention:

- Train staff in proper mounting procedures

- Use installation tools suited to the bearing type and size

- Avoid exposing bearings to dirt, dust, or moisture

Tip: Installation mistakes are preventable with disciplined handling and careful procedural adherence.

Fatigue and Wear

Even with proper operation, mechanical fatigue eventually occurs. Repeated stress cycles create micro-cracks that develop into flaking or spalling on the raceways and rollers.

Detailed Guide:

- Causes: High load cycles, prolonged operation, inadequate lubrication.

- Effects: Noise, vibration, flaking, and eventual failure.

- Prevention:

- Monitor bearings using vibration or thermal analysis

- Replace bearings nearing the end of service life

- Avoid over-speed and load beyond design limits

Table 4: Bearing Life Cycle Indicators

| Stage | Condition | Action |

|---|---|---|

| Early | Smooth operation | Regular monitoring |

| Mid-life | Minor noise or heat | Inspect and lubricate |

| Late | Flaking or vibration | Replace bearing promptly |

Methods to Prevent Roller Bearing Failures

Preventing failure involves combining careful operation, systematic monitoring, and maintenance strategies.

Detailed Guide:

- Condition Monitoring: Use vibration sensors, temperature monitors, and acoustic devices to detect early anomalies.

- Lubrication Management: Select proper grease or oil, replenish on schedule, and automate lubrication where possible.

- Contamination Control: Implement seals, clean installation areas, and filter lubricants.

- Load and Alignment Optimization: Ensure correct load ratings, use multiple bearings for heavy loads, and regularly verify alignment.

- Training Staff: Proper installation and handling reduce human-induced failures significantly.

- Regular Inspections: Visual checks, vibration analysis, and noise monitoring allow early detection of wear or damage.

Tip: Preventive maintenance is cheaper than reactive repairs and can extend bearing life by threefold under industrial conditions.

Real-World Impact of Roller Bearing Failures

When roller bearings fail, the consequences are immediate and visible. Machinery can seize, production lines stop, energy efficiency drops, and repair costs escalate. Noise, vibration, and heat often accompany the final stages of failure, signaling urgent intervention is required.

Detailed Guide:

- Consequences: Downtime, secondary damage, reduced productivity, increased operational costs.

- Indicators to Monitor: Noise, heat, vibration, lubricant discoloration, surface wear.

- Preventive Measures: Consistent maintenance, condition monitoring, and addressing minor issues early.

Table 5: Failure vs Prevention Benefits

| Scenario | Impact | Preventive Action | Result |

|---|---|---|---|

| Bearing fails unexpectedly | Production stops, equipment damaged | Routine monitoring | Reduced downtime |

| Early wear detected | Minor vibration, no stoppage | Lubrication and alignment check | Extended life, smooth operation |

| Controlled maintenance | No noise, optimal performance | Regular inspection schedule | Maximized efficiency |

FAQs

Q1: How often should roller-bearing be inspected?

A: Depending on load and speed, inspections can range from monthly to quarterly. Use vibration and temperature as primary indicators.

Q2: Can contaminated lubricant cause immediate failure?

A: Not immediately, but over time, even microscopic particles can scratch surfaces and accelerate wear.

Q3: Are all bearings affected equally by misalignment?

A: No. Spherical roller bearing tolerate misalignment better than cylindrical or tapered types.

Q4: How do I know if a bearing is overloaded?

A: Signs include excessive heat, indentations, noise, and vibration. Check the load rating against actual operating conditions.

Q5: Is automated lubrication necessary for all machinery?

A: Not always. It is most beneficial for high-speed, continuous-operation equipment where manual lubrication is insufficient.

Conclusion

Roller bearing may operate silently, but their impact on machinery performance is immense. Failures, whether caused by contamination, misalignment, overloading, improper handling, or fatigue, can disrupt operations, increase costs, and shorten equipment lifespan. Understanding these common causes allows maintenance teams and operators to act proactively rather than reactively. Preventive strategies—such as proper lubrication, condition monitoring, careful installation, load management, and contamination control—can dramatically extend bearing life and maintain smooth, reliable performance. Regular inspections and timely replacement of worn components ensure that small issues do not escalate into costly failures. By implementing structured maintenance practices and paying attention to operational details, businesses can keep their machines running efficiently, reduce downtime, and improve overall productivity. Ultimately, roller-bearing are more than just mechanical parts; they are critical enablers of precision, reliability, and consistent performance in every system they support. Understanding their vulnerabilities and actively protecting them transforms potential failures into opportunities for longevity and efficiency.