Industrial robots have become a cornerstone of modern manufacturing, handling tasks ranging from assembly and welding to packaging and inspection. The accuracy and reliability of these robots are essential because even minor deviations in movement can lead to product defects, reduced efficiency, or increased operational costs. While motors, sensors, and software often receive the most attention, one component plays a critical, yet frequently overlooked role in maintaining precision: robot arm bearings.

Bearings are mechanical elements that enable smooth rotation or linear motion in robotic joints. They reduce friction, support varying loads, minimize backlash, and dampen vibrations, all of which directly impact the repeatability and accuracy of a robot’s movements. The choice of bearing type, material, design, and maintenance practices can make a significant difference in robotic performance. Selecting the right bearings ensures that robotic arms operate smoothly under heavy loads, high speeds, and complex motion patterns without compromising precision.

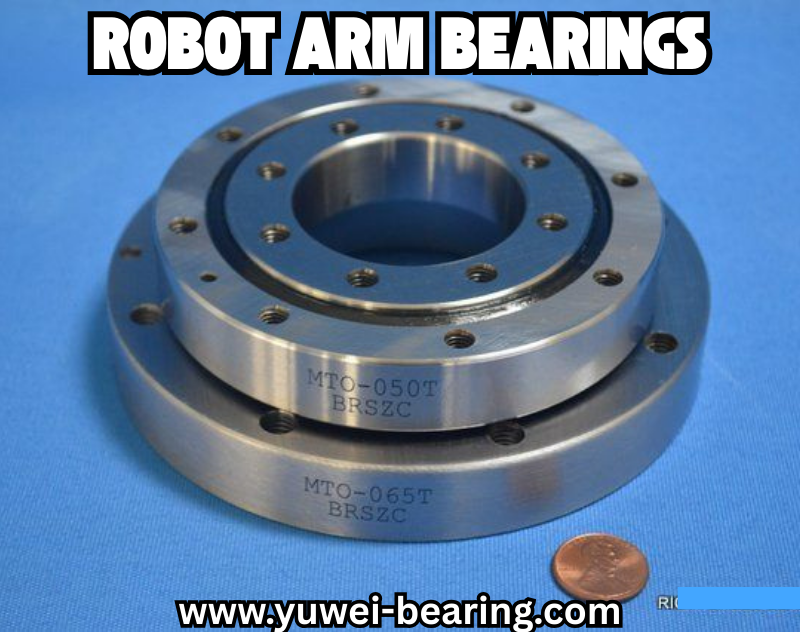

Robot Arm Bearings Improving Precision in Industrial Robotics

In this guide, we will explain how robot arm bearings work, their types, materials, design considerations, maintenance practices, and emerging trends that help industrial robots maintain optimal precision.

Industrial robots rely heavily on precision to maintain productivity, accuracy, and quality in manufacturing processes. While much focus is placed on software and motors, robot arm bearings are critical mechanical components that ensure smooth and precise movement. This guide will cover bearings’ roles, types, materials, design, maintenance, emerging trends, and tips for selection, using a practical and straightforward approach. Visit here!

Understanding Robot Arm Bearings

Robot arm bearings are mechanical components that allow smooth rotation or linear motion in robotic joints. They reduce friction, support loads, and maintain alignment of the moving parts. A robotic arm has multiple joints, such as base, shoulder, elbow, and wrist, each requiring reliable bearings to function efficiently.

Key Points:

- Bearings reduce friction, allowing consistent movement.

- They support radial, axial, or combined loads depending on joint design.

- Properly selected bearings minimize backlash, vibrations, and positional errors.

Bearings’ role in industrial robotics is to convert motor torque into precise joint motion. Misaligned or worn bearings can reduce repeatability, cause vibrations, or increase wear in other components.

Table 1: Bearing Function Overview

| Function | Description |

|---|---|

| Friction Reduction | Smooths joint movement, reducing resistance |

| Load Support | Handles radial, axial, or combined loads |

| Alignment Maintenance | Keeps robot arm bearings parts in correct orientation |

| Backlash Reduction | Minimizes small movements when changing direction |

| Vibration Dampening | Reduces motion deviation at high speeds |

How Bearings Influence Robotic Precision

The precision of a robotic arm depends on repeatability and accuracy. Bearings influence both by controlling friction, backlash, load distribution, and vibration.

Factors Affected by Bearings:

- Friction Control: Bearings reduce surface friction, ensuring smooth and predictable motion.

- Load Distribution: Bearings spread the load across the joint, preventing deformation.

- Backlash Reduction: Tight tolerance bearings minimize free play, improving positional accuracy.

- Vibration Dampening: Bearings absorb micro-vibrations, allowing the end-effector to maintain precise alignment.

List of Effects on Precision:

- Smooth joint rotation prevents errors during high-speed operation.

- Uniform load support prevents bending or misalignment.

- Tight tolerance bearings reduce backlash and maintain consistent position.

- Vibration control ensures stable motion even under dynamic loads.

Bearings directly impact robotic performance: even a small improvement in bearing quality can reduce positional errors by fractions of a millimeter, which is critical for assembly, machining, and inspection tasks.

Common Types of Robot Arm Bearings

Robot arm bearings use different bearings depending on load, speed, and joint type. The most common types include:

- Ball Bearings

- Handle moderate loads and allow high-speed rotation.

- Smooth motion with low friction.

- Common in wrist and elbow joints.

- Angular Contact Bearings

- Support both radial and axial loads.

- Tight tolerances reduce play and improve repeatability.

- Ideal for joints requiring stiffness and precision.

- Roller Bearings

- Designed for higher loads than ball bearings.

- Handle heavy forces in base or shoulder joints.

- Reduce deflection under load, maintaining accuracy.

- Crossed Roller Bearings

- Can carry loads in multiple directions.

- Provide high stiffness and minimal backlash.

- Used in precision-critical joints like robotic wrists.

Table 2: Bearing Type Comparison

| Bearing Type | Load Capacity | Friction | Typical Use | Precision Level |

|---|---|---|---|---|

| Ball Bearings | Moderate | Low | Wrist, elbow | Medium |

| Angular Contact | High | Low | Precision joints | High |

| Roller Bearings | Very High | Medium | Base, shoulder | Medium-High |

| Crossed Roller | High | Very Low | Precision joints | Very High |

Bearing Material and Its Impact on Precision

Materials influence friction, wear resistance, and thermal expansion, all of which affect precision. Common materials include:

- Chrome Steel

- High hardness and durability

- Suitable for most industrial robots

- Balanced cost and performance

- Stainless Steel

- Corrosion-resistant

- Used in cleanroom or food-grade robotics

- Slightly heavier and more expensive

- Ceramic Bearings

- Lightweight, heat-resistant, low friction

- Ideal for high-speed or high-precision joints

- Costly but improves repeatability and reduces maintenance

Material Selection Guide:

- Chrome Steel: Standard industrial applications, moderate precision.

- Stainless Steel: Corrosion-prone environments, medium precision.

- Ceramic: High-speed or micro-positioning tasks, high precision.

Key Design Considerations for Optimal Precision

Designing robot arm bearings requires careful attention to load, tolerance, lubrication, and speed.

Guidelines for Bearing Design:

- Load Capacity: Must support static and dynamic forces.

- Tolerance and Fit: Tighter tolerances reduce backlash.

- Lubrication Method: Proper lubrication reduces friction and wear.

- Speed Ratings: Bearings must handle operational speed without overheating.

- Joint Configuration: Bearings should match the direction and type of load.

List of Practical Considerations:

- Evaluate expected joint loads and movements.

- Select bearings that maintain alignment under full load.

- Ensure lubrication is compatible with operating temperature.

- Design for minimal backlash in critical joints.

- Confirm the bearing material suits the environmental conditions.

Maintenance Practices to Ensure Bearing Precision

Even the highest-quality bearings lose efficiency without proper maintenance.

Key Maintenance Practices:

- Regular Inspection: Check for wear, misalignment, or vibration.

- Lubrication Schedule: Follow manufacturer guidelines for grease or oil.

- Temperature Monitoring: Bearings expand with heat; monitor to maintain tolerances.

- Replacement Intervals: Replace before bearings reach the end of their rated lifespan.

Table 3: Maintenance Checklist

| Maintenance Step | Frequency | Purpose |

|---|---|---|

| Visual Inspection | Monthly | Detect wear or misalignment |

| Lubrication | Weekly/Monthly | Reduce friction and wear |

| Temperature Check | Weekly | Prevent overheating |

| Vibration Monitoring | Continuous | Detect abnormal motion |

| Replacement | As per rating | Maintain accuracy |

Precision Improvement Metrics

Bearings can improve repeatability and accuracy through proper selection and maintenance. Key metrics include:

- Repeatability: Ability to return to the same position consistently.

- Accuracy: Ability to reach a target position precisely.

- Backlash Reduction: Less mechanical play improves both repeatability and accuracy.

- Load Handling: Bearings that handle high loads prevent deflection, maintaining precise positioning.

Example Metrics Table

| Metric | Ideal Value for Precision Robotics |

|---|---|

| Repeatability | ±0.02 mm |

| Accuracy | ±0.05 mm |

| Backlash | <0.01 mm |

| Load Deflection | <0.1 mm under rated load |

Emerging Trends in Robot Arm Bearings

Robot arm bearings are evolving with technology. Key trends include:

- Hybrid Bearings: Ceramic rolling elements with steel races for low friction.

- Integrated Sensors: Monitor load, vibration, and temperature for predictive maintenance.

- Advanced Coatings: Reduce friction, resist corrosion, and extend life.

- 3D-Printed Components: Customized bearings for space or load-specific applications.

These trends allow robotic arms to achieve higher precision, reliability, and longevity while reducing operational costs.

Tips for Selecting Bearings for Maximum Precision

To ensure maximum precision in industrial robotics:

- Match bearing type to joint load and movement.

- Prioritize tight tolerance bearings for critical joints.

- Consider lubrication and environmental factors.

- Ensure easy maintenance access to reduce downtime.

- Balance cost and performance—high-quality bearings reduce operational errors.

Table 4: Bearing Selection Checklist

| Factor | Consideration |

|---|---|

| Load | Static and dynamic forces |

| Precision Requirement | Tolerance, backlash, repeatability |

| Environment | Temperature, humidity, contamination |

| Speed Requirement | Max RPM of the joint |

| Maintenance Accessibility | Ease of inspection and replacement |

| Material | Steel, stainless, ceramic |

FAQs About Robot Arm Bearings

Q1: How often should robot arm bearings be replaced?

A: Bearings should be replaced based on manufacturer ratings or if inspection shows wear, vibration, or increased backlash.

Q2: Can all joints use the same type of bearing?

A: No. High-load joints need roller or crossed roller bearings, while low-load joints can use ball bearings.

Q3: Does lubrication affect precision?

A: Yes. Proper lubrication reduces friction and wear, maintaining smooth motion and repeatability.

Q4: Are ceramic bearings better than steel?

A: Ceramic bearings offer lower friction and high-speed performance, but are costlier. They are ideal for precision-critical joints.

Q5: What is the main factor affecting bearing accuracy?

A: Tolerance, load handling, and friction are the main factors influencing precision.

Conclusion

In industrial robotics, precision is not just a performance metric—it is a requirement. Every movement, every joint, and every task relies on components that can deliver consistent accuracy, and robot arm bearings are among the most critical of these components. By reducing friction, supporting loads, minimizing backlash, and dampening vibrations, bearings directly influence the repeatability and reliability of robotic operations. Choosing the right bearing type, material, and design ensures that robotic arms can handle complex motion patterns, high speeds, and heavy loads without compromising performance.

Regular maintenance, proper lubrication, and monitoring are equally important to preserve bearing function and extend operational life. Emerging trends, such as hybrid bearings, sensor-integrated designs, and advanced coatings, are further enhancing precision and reducing downtime in industrial environments. Investing in high-quality, well-maintained bearings does not just improve movement accuracy—it boosts productivity, reduces errors, and supports long-term operational efficiency.

Ultimately, the role of robot arm bearings in robotic precision cannot be overstated. They are foundational elements that enable robots to perform reliably day after day, meeting the exacting demands of modern manufacturing while ensuring optimal efficiency and output.